Where are Trampolines Made?

An Insight into Chinese Trampoline Manufacturing

Many of the products bought by Australian consumers are manufactured in China and trampolines are no exception. However, just because a trampoline has been ‘made in China’ it doesn’t mean that it’s of inferior quality. In recent years, thanks to western input regarding quality, designs, and materials, the standard of products has improved and we highly recommend our Australian designed Chinese made trampolines.

At Web and Warehouse, we’ve seen many improvements and changes since we began our importing and manufacturing experience in China. However, we are still amazed by how the manufacturing processes can differ so much from those in Australia.

Automation is Key in Australian Factories

Automation is Key in Australian Factories

Importing products from China came about in an organic way; when we were looking to source quality products for our family and like most people in Australia and the wider world, until then we gave little thought to how products were made or who by.

We knew how manufacturing worked in Australia as Andrew had worked in an Australian factory for 30 years where, right from the start of his apprenticeship, everything was done by machine. During his time in the factory, he watched as production levels increased and improvements were made in both safety and quality. However, as computers took over many of the manual checks and processes, the amount of manpower needed to manufacture the product was greatly reduced.

Our First Visit to a Chinese Factory

When we made our first visit to a Chinese factory, we had a broad expectation that their processes would probably be like they were in Australian factories 30 years ago, in that most processes would be carried out by machines but with a fair amount of manual labor to support them.

How wrong we were! In fact, when we visited our first trampoline factory, we were overwhelmed by the huge amount of manpower needed to do everything. Can you imagine a factory without a forklift? This factory used primitive-looking rolling tools to move their products. I'm talking huge bolts of mat and pad materials and truckloads of steel. Even the brooms were handmade of bamboo and their mops were made from scrap materials. Resourceful? Yes, but certainly not what we expected to see.

Teams of Workers Carried Out Everything by Hand

Teams of Workers Carried Out Everything by Hand

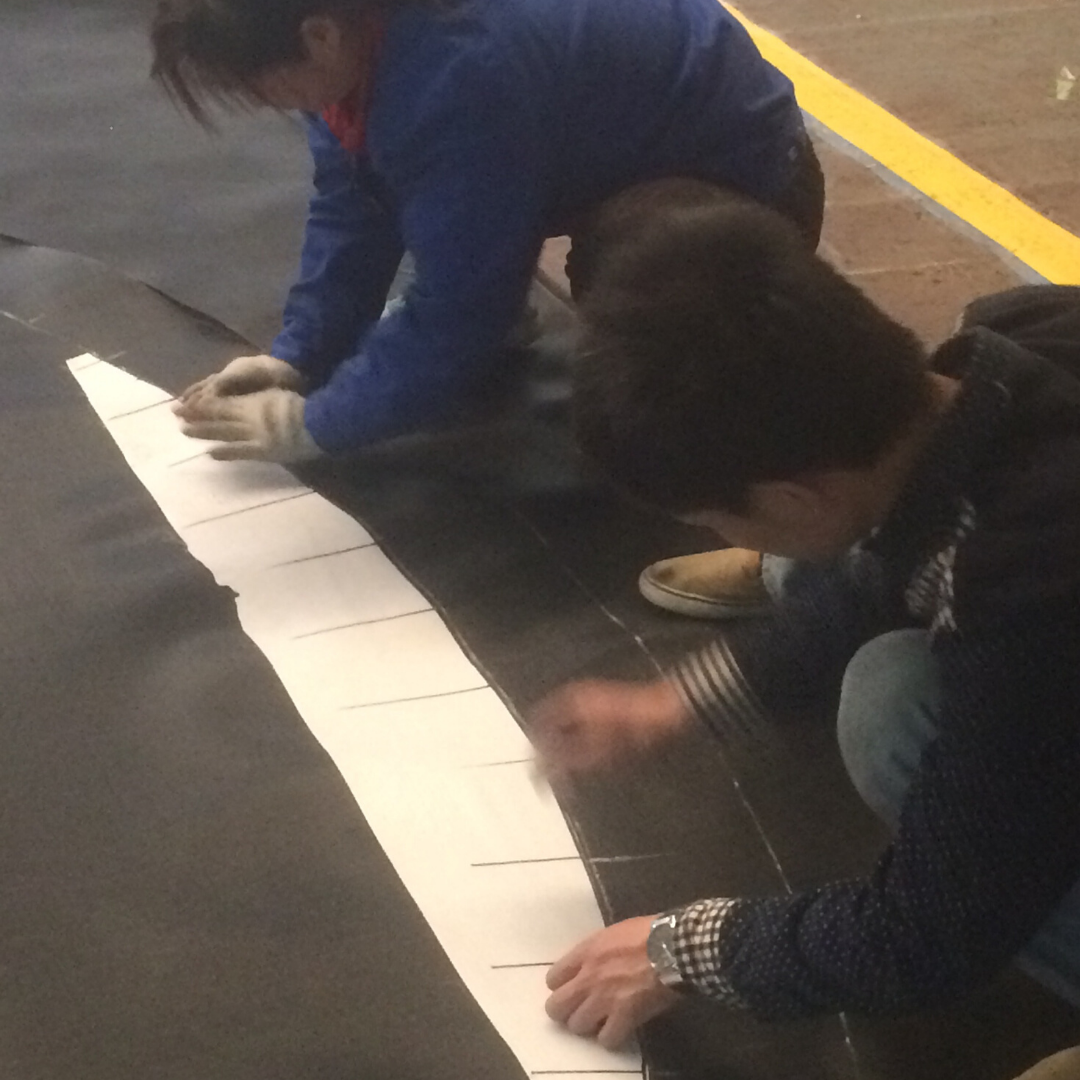

Every process was done by hand and needed a team of 6-8 workers. The saying, ‘many hands make light work’ could have been invented in this factory. There was even a team to open the gate for drivers, take messages, accept parcels, and carry out whatever other tasks came to hand. There were teams to unload trucks and stack rolls of material or steel tubing. There were teams to move materials to the workstations for cutting, welding, folding, and sewing.

It was quite a reality check to see that far from being automated or machine-assisted, every job from putting in screws to folding boxes was done by hand. The cutting was done manually, the springs were sorted and counted and put into bags by hand and then passed to someone who would weigh the bags before passing them along the ‘production line’ to be sealed.

The factory did employ skilled workers to carry out tasks such as welding or sewing. Every single label was sewn in and we saw rows and rows of women working on sewing machines. Some tasks required total concentration and so it was, all heads down and no talking, while workers carrying out less complicated tasks were able to chat and exchange banter with each other.

As the staff worked, a number of production managers checked the quality and workmanship before items were sent to the next group to fold and label in preparation for the packing room.

In addition to the production staff, there were teams of workers employed to wipe down the parts so that they are clean and ready for the packing crew whose job it was to fit some parts together to help with assembly before bagging and packing the parts ready for placing in the cartons. The packing line comprised of many people who put their one or two parts into the box as it passed them until finally the box lid was put on and it was secured with strapping or tape, weighed and then put aside ready to go into the container for final shipping.

How many Trampoline factories are in China

How many Trampoline factories are in China

There are about 50 factories equipped to manufacture trampolines in China but really only 30 main factories to consider. Of the 30 less than 10 of them do 80% of the global supply.

In deciding on a factory we visited quite a few factories after we had sorted through many based on communications online and once onsite we looked closely at the maintenance, tidiness, cleanliness, and staff body language and interactions before deciding on one. We wanted a factory to work with us for Australian standards, always with safety, quality, and bounce in mind for our customers.

The factory we have settled on is based in northern China. Many factories win their work purely based on price comparing who can do "Cheaper, Cheaper, Cheaper" This is where short cuts are made on business ethics in materials supplied, workers conditions, and the final product.

Our factory owners a father-son and cousin enterprise. The cousins have both studied and worked in the UK before returning to manage and redefine the father's factory. They have a lot of family members working for them in the management roles of various teams. They are a delightful lot of people we are now happy to call our friends. We socialize with their families in the evening when staying, have named two of their babies with their English names.

Machines and Automation Arrive – But ‘Handmade’ is Still the Norm

Since our first visit twelve years ago, there have been many changes made to the way in the factories work. Our current factory now has forklifts together with container ramps and overhead cranes and the packing line is now automated with a conveyor belt, while some of the weldings are done by robots. All springs are made in the factory, they now also have their own on site powder coating facility.

However, overall, most of the production and packing is still done by hand.

So, the next time you bounce on your trampoline, spare a thought for the manhours of work that has gone into it and the fact that it has been handmade!

Related Products

$1,099

GeeTramp Force 7ft x 10ft Rectangle Trampoline1 out of 5 stars

2 out of 5 stars

3 out of 5 stars

4 out of 5 stars

5 out of 5 stars

24 reviews

$1,249

GeeTramp Force 8ft x 12ft Rectangle Trampoline - Standard1 out of 5 stars

2 out of 5 stars

3 out of 5 stars

4 out of 5 stars

5 out of 5 stars

44 reviews

$1,649

GeeTramp Force 9ft x 14ft Rectangle Trampoline - Standard1 out of 5 stars

2 out of 5 stars

3 out of 5 stars

4 out of 5 stars

5 out of 5 stars

45 reviews

$1,849

GeeTramp Force 9ft x 14ft Rectangle Trampoline - High Bounce1 out of 5 stars

2 out of 5 stars

3 out of 5 stars

4 out of 5 stars

5 out of 5 stars

84 reviews

$2,249

GeeTramp Force 9ft x 14ft Rectangle Trampoline - High Bounce /w AU Springs1 out of 5 stars

2 out of 5 stars

3 out of 5 stars

4 out of 5 stars

5 out of 5 stars

23 reviews

$1,399

GeeTramp Force 8ft x 12ft Rectangle Trampoline - High Bounce1 out of 5 stars

2 out of 5 stars

3 out of 5 stars

4 out of 5 stars

5 out of 5 stars

44 reviews