GeeTramp 175x28mm Spring - AU

Description

Australian made springs!

Australian steel, Australian wire, Australian made.

This spring has a custom extended hook at one end.

Most galvanised springs on the market are made with short hook ends at both ends, this means they normally only fit on a frame edge attachment system on the inside of the frame tube (like wriggle wire which are usually found on high performance rectangle trampolines commonly found in gymnasiums or high end outdoor rectangle trampolines)

The custom extended hook provides extra clearance at one end, this enables it to also fit normal round tubed frames which have a spring slot in the top of the tube. This spring therefor will fit both styles of frames.

What is the difference between this spring and the standard zinc coated springs?

The Australian spring wire is made according to AS 1472 (Carbon steel spring wire for mechanical springs) with high grade and high quality metallurgical properties from the required carbon, silicon and manganese content. This provides the tensile strength necessary for a smoother, higher bounce while enabling tough long life performance.

The spring is made with the hot dip galvanising process, while not quite as aesthetic as the normal zinc plated imported springs the coating in comparison is thick which enables the proven extra-long life in the outdoors environment.

As a general rule you would use these springs if your trampoline already has this style of spring because compared to the standard springs these springs stretch substantially longer and because of this the mat is sized to match.

Will suit many high performance brands however we recommend purchaser carefully measures their existing Springs to compare sizes prior to purchasing.

If you are missing even one or two Trampoline Springs you are best to get replacement springs to keep your trampoline in a safe condition. Once one Spring is out of action the Springs on either side take on additional load which leads to an increasing cycle of more failures. This also applies to the Jumping Mat attaching points so in addition to more Spring failures the Jumping Mat is also likely to have more points fail.

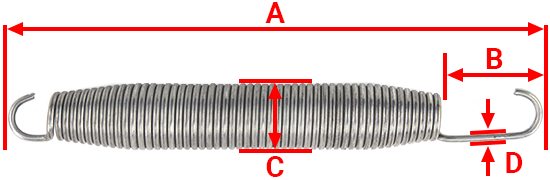

A = 175mm (7")

B = 38mm

C = 28mm

D = 3.1mm

Measurements can vary ± 2mm, between manufactured batches. Use sizes shown as a guide and please contact us if you need clarification.

Reviews

There are no reviews for this product yet.